Stamped Concrete Patio Costs in Midland: Key Factors

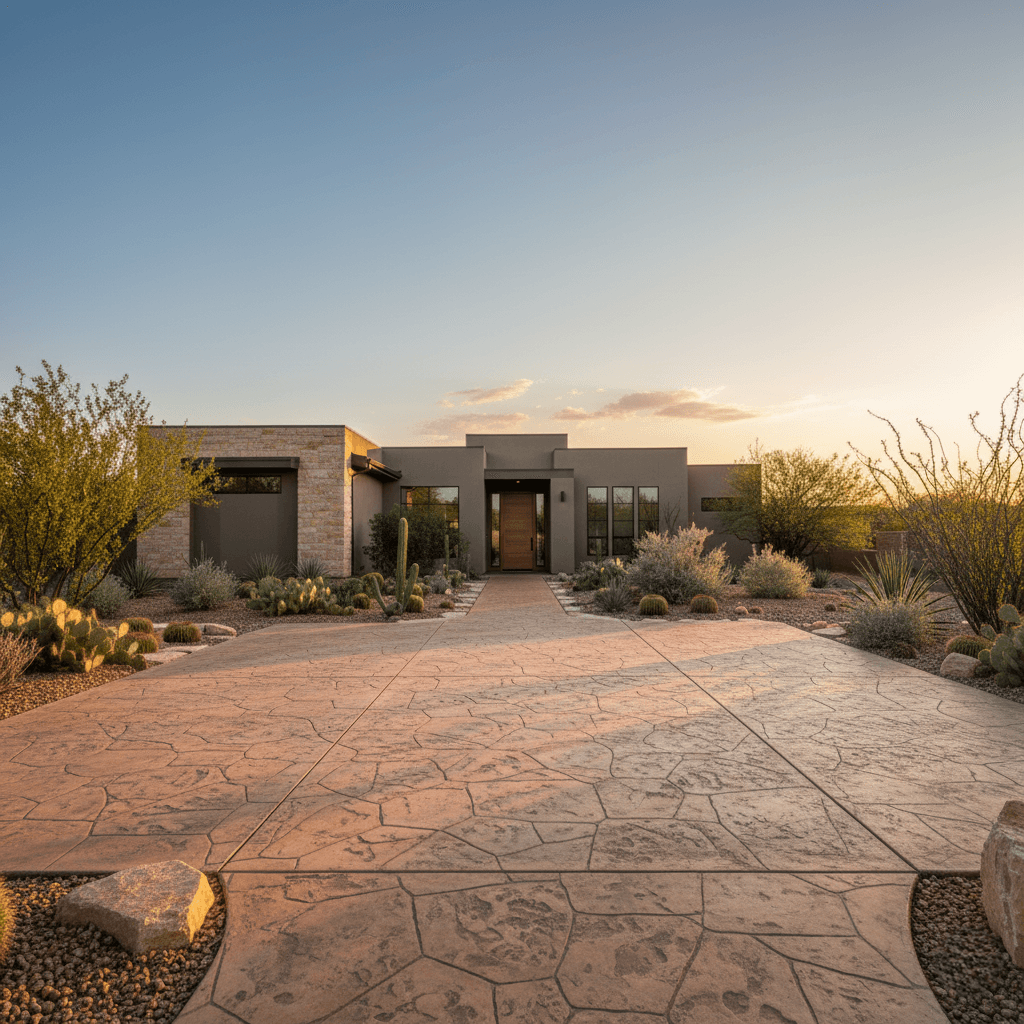

Stamped Concrete Patio Midland

Understanding stamped concrete patio pricing in Midland requires consideration of multiple variables that influence the final project cost. Material costs, labor rates, design complexity, and site preparation requirements all contribute to the total investment homeowners can expect. Local market conditions in West Texas affect pricing structures, while seasonal demand fluctuations may impact contractor availability and rates. Professional installation ensures proper execution of complex stamping techniques that create lasting, attractive surfaces. Quality workmanship prevents common problems like pattern irregularities, color inconsistencies, or premature wear that can compromise both appearance and durability over time.

Base Cost Structure and Pricing Ranges

For example, a stamped concrete patio will cost anywhere from $9 to $16.25 per sq ft. The cost of stamped concrete varies between $8 to $19 per sq ft. Both of these are examples of where you could begin budgeting for the cost of a stamped concrete patio; however, the final cost of your project will largely be determined by the specifics of your job, such as the amount of material needed, the amount of design detail you want in your patio, and what you want it to look like.

For example, a 20 x 20 stamped concrete patio would have an estimated price range of $3,200 to $7,600. As you can see, the price of the patio will increase as the size of the patio gets bigger. With larger projects, you will generally save money because the company doing the work has to buy more materials at one time, which means they will have a lower cost per sq ft. Also, large jobs tend to have more opportunities for efficiency in terms of installation, as well as in terms of getting the job done faster.

Average Cost of Pad Installation

The average cost of a pad installation in Midland County was $663.00 to $756.00 in 2025. This cost is for a standard pad installation. It is not for a decorative stamped patio installation that has many of the same installation costs as the standard installation; however, decorative stamped patio installations have many more costs associated with them, specifically, the cost of using decorative stamping techniques and decorative materials.

Premium Design Prices

You can get a basic stamped concrete slab installed for as low as $7.00 per sq ft, and as much as $25.25 per sq ft if you have decorative hand-applied accents put on the slab. More complex designs, such as intricate custom patterns, will cost more money because the installer will need to use more advanced tools, and the installer will need to spend more time to finish the job correctly. Multi-colored slabs are also going to cost more money than single-colored slabs because the installer will need to purchase more materials, and the installer will need to apply the second color in addition to the first color, and then there is the additional time involved with applying two colors. Decorative hand-applied accents are also going to cost more money than a standard installation because the installer will need to use specialized skills to do the job correctly.

Effect of Pattern Selection on Project Pricing

Different patterns will cost differently to implement. Basic patterns such as Ashlar Slate, Running Bond, and Cobble Stone are going to cost less money to install than more intricate patterns. That is because the installer will need to use less complicated tools, and the installer will not need to spend as much time finishing the job. When you select a multi-colored pattern, you will also pay more money to install the pattern. That is because the installer will need to purchase more materials to accomplish the task, and the installer will need to take more time to finish the job; therefore, the installer will charge you more money to complete the task. Patterns that include hand-applied decorative accents will also cost more money to install than standard patterns. That is because the installer will need to possess specialized skills to do the job correctly, and the installer will need to spend more time to complete the job.

Patterns Used Around Landmarks

Several landmarks in the Midland area showcase decorative stamped concrete installations in both commercial and residential settings. These installations are great examples of how the complexity of the design and the design itself will dictate the level of investment in your project.

Effects of Material Quality on Project Pricing

There are different strengths of concrete that can be used for residential applications, depending on the intended use and environment. Residential applications generally call for 3000-4000 psi concrete, while high-traffic areas may require 5000 psi or stronger. Higher-strength concrete costs more, but it offers better durability and requires less maintenance over the years.

Effects of Site Prep on Project Pricing

It is very important to properly prepare the site prior to the concrete installation. Site prep affects the long-term performance of the installation and will ultimately affect the cost of the installation. The amount of excavation, the condition of the soil, and whether or not the area drains properly will all affect the cost of the installation. Poor-draining or unstable soils will necessitate extra prep work, which will increase the base cost of the installation prior to the installation of the concrete.

Preparation of the Grading and Leveling of the Area

The grading and leveling of the area will ensure that the water will drain properly off the area while providing a solid foundation for the placement of the concrete. While compacted gravel bases are used to stabilize the area and provide drainage, the thickness of the gravel base will depend on the condition of the soil and the weight-bearing requirements of the area. In some areas, a vapor barrier may need to be placed under the gravel base to prevent moisture issues in the future. The cost of the vapor barrier will depend on the product being used.

Removal of Old Surface

If the old surface is to be removed prior to the installation of the new surface, this will add to the cost of the project. There are different charges for the removal and disposal of old concrete, asphalt, and other materials. The charge for the removal and disposal will depend on the type of material being removed, the thickness of the material, and the cost of disposal in the local area. An experienced contractor will determine the best method for preparing the site to meet the performance requirements of the installation while minimizing the cost of the project.

Weather-Specific Requirements

Due to the extreme temperatures and occasional severe weather that occur in West Texas, special precautions must be taken to ensure the long-term performance of the installation. Professionals in the industry will take into account the local requirements when designing and installing the project.

Installation and Labor Costs

The installation of decorative stamped concrete requires highly-trained technicians who have extensive experience with decorative stamping, color application, and finishing. Typically, labor accounts for 40-60% of the total project costs, and the level of skill and training required to complete the job will greatly affect the labor costs. The level of complexity of the design will affect the number of man-hours required to complete the project, and the number of technicians working on the project will affect the amount of time it takes to complete the project. The technician may have to wait for favorable weather conditions to complete the installation, which may cause delays in the completion of the project and increase labor costs due to overtime or seasonal rates.

Quality Control

During the installation process, quality control is essential to avoid costly repairs and replacements. Professional contractors will consistently apply color, align patterns, and complete the surface finishes so that the final appearance and performance of the installation will meet quality standards. Technicians with years of experience will work efficiently while meeting quality standards, which justifies paying for professional installation services.

Seasonal Demand

When there is a high demand for construction services, particularly during peak spring and fall seasons, the availability of contractors may be limited, and prices may be affected. Professional contractors may offer better pricing during the slow season to remain active and available for optimal installation conditions.

Economies of Scale

As the size of the project increases, the cost per sq ft of the project decreases. Larger projects allow for greater economies of scale for contractors to purchase materials and reduce overhead costs. Contractors can also pass along the benefits of economies of scale to customers through lower costs. In order to realize the potential cost savings that are offered through economies of scale, contractors will typically require a minimum project size.

Configuration of the Project

The configuration of the project will affect the cost of the project through edge work, corner details, and transition of the pattern. Rectangular shapes with straight lines are easier to build and cost less than a project with multiple angles, curves, and/or integrated features. Planters, seating areas, and decorative borders will add to the cost of the project, but will also contribute to its beauty.

Multiple Area Projects

Combining multiple concrete areas, such as a patio, walkway, and driveway, may result in cost savings for the customer due to shared mobilization and bulk material purchases. Multiple areas with similar design elements will result in a unified appearance and maximize installation efficiencies to benefit overall project pricing.

Market Conditions and Competition

Prices for stamped concrete are influenced by the Midland area’s construction market through the availability of materials, the number of competing contractors, and the regional economic conditions. Materials purchased locally will affect material costs, while transporting materials from distant locations may increase material costs for specialty items and colors. Established contractor networks will often provide competitive pricing through efficient operations and local expertise.

Seasonal Activity and Contractor Availability

Contractor availability and pricing will be affected by the time of year and seasonal demand. High-demand periods may lead to premium pricing, while slower periods may provide better pricing and flexible scheduling for homeowners. Professional contractors will manage their workload while maintaining competitive pricing throughout the year.

Residential vs Commercial Focus

Whether a contractor focuses on residential or commercial markets will affect their pricing structure and availability. Some contractors will focus exclusively on residential work, offering competitive pricing for homeowner projects, while others may focus on commercial projects, which may affect their residential pricing.

Regional Standards of Craftsmanship

Homeowners near landmarks such as the Haley Memorial Library and History Center will find examples of high-quality concrete work that reflect regional craftsmanship standards. Examples of local craftsmanship will assist homeowners in establishing expectations for quality work in the area.

Additional Services and Features

Stamped concrete sealing ranges from $0.10 to $0.20 per sq ft, depending on the type of sealant used. Sealing protects the surface from damage caused by weather and improves the appearance of the surface. Additional costs for decorative borders, saw-cut patterns, and accent colors will provide added visual interest and increase project costs for additional labor and materials. Integrating features such as fire pit surrounds, built-in seating, and planter areas will require specialized forming and installation techniques. These features will add functional and aesthetic appeal to the project while requiring additional expertise and costs.

Value Added Benefits

High-quality installation and materials will provide a durable surface that will minimize maintenance costs and replacement needs. Professional contractors will ensure proper drainage, consistent pattern layout, and surface preparation to prevent common problems that will require costly repairs.

Financing and Budget Planning

Project financing may affect the overall cost of the project through interest costs or payment timing requirements. Some contractors will provide financing options to allow homeowners to complete larger projects while allowing them to pay for the project over an extended period. Homeowners may receive cash payment discounts to lower the overall cost of the project if they have sufficient funds to pay for the project in advance.

Timing of the Project

Both pricing and project scheduling will be affected by the timing of the project. Optimal installation times are typically found during periods of mild weather. Completing a project during a slower construction period may provide cost savings to homeowners while providing sufficient contractor time and effort to complete the project correctly.

Permits and Fees

Permit fees and associated permits will add to the cost of the project but will ensure compliance with building codes and standards. Professional contractors will handle the permit process while including the associated costs in the project estimate.

At Midland Concrete Services, we provide clear and accurate pricing and estimates to help homeowners understand all aspects of their stamped concrete patio investment. Our knowledgeable staff will provide you with the highest quality service through professional installation and long-lasting results that will enhance your outdoor living experience.