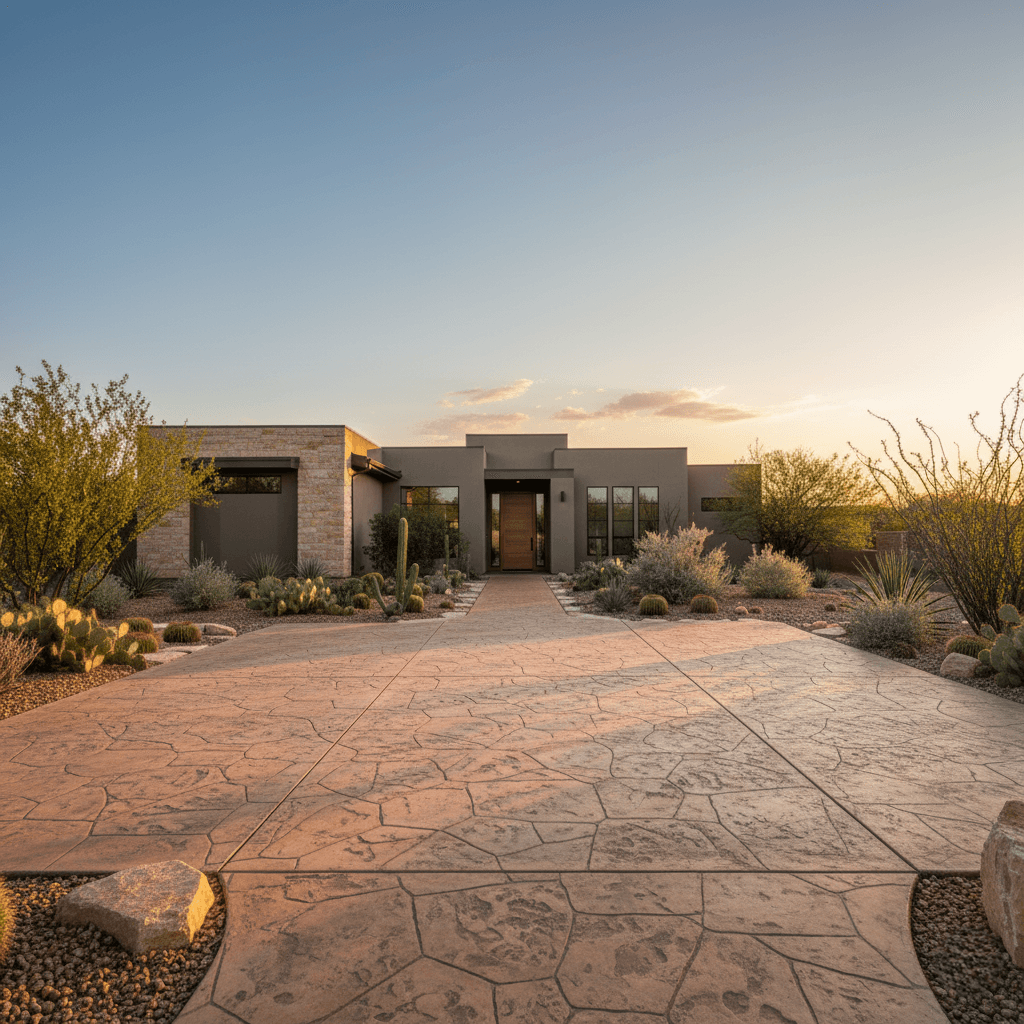

Long-Term Care Tips After Concrete Resurfacing in Midland

Concrete Resurfacing Midland

Proper maintenance following concrete resurfacing ensures maximum return on your investment while preserving both appearance and structural integrity for years to come. The first few months after installation prove critical in establishing protective routines that prevent common problems like staining, cracking, or premature wear. Understanding Midland’s unique climate challenges helps homeowners develop maintenance schedules that account for temperature extremes, UV exposure, and occasional severe weather events. Professional resurfacing creates renewed surfaces that require different care approaches compared to original concrete installations. With proper care and maintenance, resurfaced concrete can last 5-10 years or even longer, making consistent upkeep practices essential for protecting this valuable home improvement investment.

Initial Curing and Break-In Period

The first 30 days following concrete resurfacing represent the most critical period for long-term performance. During this time, the new surface continues curing and achieving full strength, requiring careful protection from excessive moisture, heavy loads, and chemical exposure. Avoid parking vehicles, placing heavy furniture, or conducting activities that might damage the developing surface during this initial period.

Temperature control becomes particularly important in Midland’s climate, where rapid temperature changes can stress curing concrete. Professional contractors typically recommend avoiding extreme temperature exposure during the first week, including protection from direct sunlight during peak afternoon hours when possible.

Moisture management during the curing period requires a balance between adequate hydration and protection from water damage. Light misting may be beneficial in extremely hot, dry conditions, while excessive water exposure from irrigation systems or heavy rain should be minimized through proper drainage and temporary protective measures.

Early Inspection and Documentation

Photograph your newly resurfaced concrete from multiple angles during optimal lighting conditions to establish baseline documentation for future reference. This visual record helps track changes over time and provides valuable information for warranty claims or maintenance planning. Note any initial surface characteristics, color variations, or texture patterns that represent normal installation outcomes.

Regular Cleaning Protocols

Establishing consistent cleaning routines prevents dirt accumulation, stain penetration, and surface deterioration that can compromise resurfaced concrete’s appearance and performance. Regular cleaning involves multiple approaches depending on soil conditions, usage patterns, and seasonal requirements specific to West Texas environments.

Weekly sweeping removes abrasive particles that can gradually wear surface textures and finishes. Use soft-bristled brooms or leaf blowers to avoid scratching delicate decorative surfaces. Areas near landmarks like the Sibley Nature Center, which attracts families and foot traffic, may require more frequent cleaning due to increased debris accumulation.

Monthly deep cleaning using appropriate concrete cleaners removes embedded dirt and prevents staining. Choose pH-neutral cleaners specifically formulated for decorative concrete to avoid damaging colored or textured surfaces. Avoid harsh chemicals, acidic cleaners, or deicing agents that can cause surface damage or discoloration.

Stain Prevention and Immediate Response

Prompt attention to spills prevents permanent staining that may require professional restoration. Oil, grease, food, and beverage spills should be cleaned immediately using appropriate cleaning agents and techniques. Blot rather than scrub initially to avoid spreading stains or driving them deeper into the surface.

Seasonal debris from trees, plants, and weather events requires timely removal to prevent organic staining. Areas near the Bush Family Home State Historic Site and other tree-lined neighborhoods experience heavy leaf fall that can create tannin stains if not addressed promptly.

Protective Sealing Schedule

We recommend resealing your concrete every two to three years, depending on exposure and usage. Sealing provides essential protection against moisture penetration, stains, UV damage, and freeze-thaw cycles that can damage resurfaced concrete surfaces. The timing and type of sealer application depend on traffic levels, weather exposure, and original surface treatments.

High-traffic areas or surfaces exposed to heavy weather may require annual sealing, while protected patios or walkways may extend sealing intervals to three years. Monitor surface water absorption by conducting simple bead tests annually to determine when resealing becomes necessary.

Professional sealer application ensures proper surface preparation, product selection, and application techniques that maximize protective benefits. DIY sealing requires careful attention to weather conditions, surface preparation, and application methods to avoid common problems like hazing, bubbling, or uneven coverage.

Sealer Selection Considerations

Different sealer types offer varying benefits and maintenance requirements. Penetrating sealers provide long-lasting protection without changing surface appearance, while topical sealers offer enhanced stain resistance and visual enhancement but may require more frequent reapplication. Discuss options with professional contractors to determine optimal choices for your specific application.

Climate-Specific Maintenance Strategies

West Texas’s climate presents unique challenges requiring specialized maintenance approaches. Prolonged exposure to high temperatures and direct sunlight can accelerate the aging process of concrete, leading to discoloration, surface cracks, and other structural weaknesses. UV protection through appropriate sealers and shade structures helps minimize solar damage while maintaining surface integrity.

Temperature extremes common in the Midland area create expansion and contraction cycles that stress concrete surfaces. Monitor control joints and expansion gaps regularly to ensure they remain clean and functional. Seal minor cracks promptly to prevent water infiltration that can cause freeze-thaw damage during cooler months.

Dust storms and high winds characteristic of the region require additional cleaning attention and potential surface protection during severe weather events. Cover decorative surfaces when possible during major dust events, and clean thoroughly afterward to remove abrasive particles that can damage finishes.

Areas near recreational facilities like Hogan Park, where the Sibley Nature Center is located, experience varied weather exposure and usage patterns that may require adjusted maintenance schedules. Higher foot traffic and organic debris accumulation necessitate more frequent cleaning and closer monitoring for wear patterns.

Seasonal Maintenance Adjustments

Spring cleaning should include thorough surface inspection, crack sealing, and deep cleaning to address winter damage and prepare for increased usage. Summer maintenance focuses on UV protection, adequate irrigation management, and heat stress monitoring. Fall preparation includes enhanced cleaning to manage increased organic debris and preparation for temperature fluctuations.

Traffic Management and Load Distribution

Resurfaced concrete surfaces require careful traffic management to prevent premature wear and damage. Heavy vehicles, equipment, and concentrated loads can compromise thin overlay systems or damage decorative finishes. Establish clear usage guidelines that protect your investment while maximizing surface utility.

Furniture placement should utilize protective pads that distribute loads and prevent point loading that can cause indentations or surface damage. Move furniture periodically to prevent permanent impressions and allow uniform wear patterns across the entire surface.

Pet considerations become important for homeowners with dogs or cats that may scratch or stain decorative surfaces. Training pets to use designated areas and prompt cleanup of accidents helps preserve surface appearance and prevents permanent damage.

Activity Zone Management

Designate high-traffic pathways and consider protective measures for areas receiving concentrated use. Entrance mats, designated walkways, and traffic flow planning minimize wear while maintaining aesthetic appeal. Regular inspection of these areas enables early intervention before damage becomes extensive.

Drainage and Water Management

Proper drainage remains critical for resurfaced concrete longevity, particularly in areas prone to heavy rainfall or irrigation runoff. Standing water can penetrate surface coatings, cause staining, and create conditions for freeze-thaw damage during cooler months. Regular inspection and maintenance of drainage systems prevent water-related problems.

Irrigation adjustments may be necessary to prevent overspray onto concrete surfaces. Sprinkler systems should be calibrated to avoid direct water contact while maintaining landscape health. Consider drip irrigation or targeted watering systems that minimize concrete exposure.

Slope maintenance ensures continued water runoff away from structures and prevents ponding in low areas. Minor adjustments using appropriate fill materials can correct drainage issues before they cause significant problems.

Winter Weather Preparations

In the cooler months, avoid using chemical deicers on your concrete surfaces. These chemicals can cause scaling and spalling by forcing the thawing and refreezing of moisture within the concrete. Use sand for traction or concrete-safe alternatives that provide safety without causing surface damage.

Professional Inspection and Maintenance Services

Annual professional inspections identify potential problems before they require costly repairs or surface replacement. Experienced contractors recognize early warning signs of wear, damage, or maintenance needs that homeowners might overlook. Professional assessment provides an objective evaluation of surface condition and maintenance effectiveness.

Specialized cleaning services may be beneficial for heavily used or severely stained surfaces that exceed homeowner maintenance capabilities. Professional equipment and expertise can restore surfaces without causing damage that might result from improper DIY attempts.

Preventive maintenance programs offered by professional contractors provide systematic care that extends surface life while maintaining warranty coverage. These services typically include scheduled cleaning, sealing, minor repairs, and condition monitoring that protects homeowner investments.

Documentation and Record Keeping

Maintain detailed records of maintenance activities, including dates, products used, weather conditions, and surface responses. This information helps establish optimal maintenance schedules while providing valuable data for warranty claims or professional consultations.

Troubleshooting Common Issues

Early identification and prompt response to common problems prevent minor issues from becoming major repairs. Surface discoloration, small cracks, or wear patterns often indicate maintenance needs or environmental factors requiring attention.

Efflorescence, the white chalky deposits sometimes visible on concrete surfaces, typically results from moisture movement and usually resolves naturally. However, persistent efflorescence may indicate drainage problems or sealing issues requiring professional evaluation.

Color changes in decorative concrete may occur naturally as surfaces age and weather. Distinguish between normal weathering and problematic changes that might indicate maintenance needs or product failures requiring professional attention.

At Midland Concrete Services, we provide comprehensive maintenance guidance and professional services to help homeowners protect their concrete resurfacing investments. Our local expertise ensures maintenance recommendations account for West Texas climate conditions while maximizing surface performance and appearance for years of reliable service.